We'll do this by drawing sets of horizontal and vertical lines at equally spaced intervals across the plan. Then for each corner of every grid cell we will determine both the existing elevation and proposed elevation at that point. The difference between the two will be the cut or fill depth for that point. Positive differences will be fill and negative differences will be cut. Then for every grid cell, we'll add up all of the cuts and all of the fills separately.

The difference between those two numbers is the import or export of dirt from the site. (Sorry Mrs. Reader) With a large T-square, draw a series of equally spaced Coors auto and vertical lines across your drawing. The lines should be spaced in multiples of your drawing scale. The spacing you choose should strike a balance between speed and accuracy. The smaller the grid cells, the more calculations will need be performed but the higher the accuracy. The larger the grid cells, the fewer calculations will need to be performed the lower the accuracy will be.

A good compromise is to base the spacing on the average complexity of the job site. In more complex areas the grid cells can be further subdivided so as to increase the accuracy in those portions of the drawing. Step 2 – Calculating the existing elevations For the corner of each grid cell, determine the existing elevation. For each section line the cut area and the fill area is determined. The volume between two sections is determined as the average area of the two sections multiplied by the distance between them. By adding together the volumes between all of the sections the total cut and fill volumes are obtained.

The cross section method involves plotting cross sections of the existing and proposed levels at regular intervals across the project site. For each of the cross sections, the cut area and the fill area is determined. The volume between each pair of sections is estimated by multiplying the average cut or fill area of the two sections by the distance between them. Once these volumes have been calculated for each pair of sections the total cut and fill volumes are obtained by adding them all together. An example calculation for the volumes between two sections of the example shown opposite.

This calculation is repeated for all of the sections, and the values are added together to get the total cut and fill volumes. There are several different methods used to determine the areas of cut and fill once the sections have been plotted. Perhaps the simplest method is to plot the sections on gridded paper and count the grid cells of the cut and fill areas. Multiplying the cell count by the area represented by each of the grid cells gives the cut or fill area for the section. Other methods include drawing the sections in CAD and exporting areas or calculating areas mathematically using the trapezoidal rule.

The spreadsheet included with this article includes formulae which have automated the process of calculating section areas using the trapezoidal rule. This can save a great deal of time if you are using the cross section method. The accuracy of the cross section method depends to a large degree on the distance you choose to set between the sections.

Closer sections improve the accuracy of the estimate, but take longer to estimate. A balance has to be made between accuracy on the one hand, and speed of generating the estimate on the other. One of the great advantages of this method is that cross sections are generated in the process. These provide a useful visual summary of the estimation, which present the cut and fill depths across the project in a very clear way. One of the disadvantages off the method is that it can be extremely laborious to extract cross sections from the drawing, and to determine the areas of the sections.

The first "by-hand" method uses the grid method to calculate cut and fill for the buildings site. In this method, the site is divided into equal sized grid squares. The grid squares are typically 1 inch to 2 inches in size on the paper plan.

For every corner of every grid square both the existing elevation and the proposed or final elevation elevation is calculated and noted on the plan. Once all of the elevations are determined, the difference between the existing elevation and the proposed elevation at each corner is noted on the plan as well. Then for each grid square, these elevation differences for each of the four corners are added together and averaged by dividing the sum by 4. If the average of the elevation differences for a grid square is negative, then this is a cut area. In cut areas, existing elevations need to be lowered down to the proposed elevations or "cut".

If the average elevation difference is positive, that means the existing elevations need to be raised to the proposed elevations or "filled". Then all of the negative numbers are added together and totaled to determine the total of the cut depths. Then the positive numbers are added together and totaled as the total fill depths. Then each of these cut totals and fill totals is multiplied by the area of the grid squares in order to determine the number of cubic feet of cut and cubic feet of fill. And finally these cut or fill volumes are divided by 27 in order determine the site's total number of cubic yards of cut and cubic yards of fill . Finally, the difference between the total cut volume and total fill volume is calculated.

If there is more cut than fill, then dirt must be removed from the building site and trucked away. If there is more fill than cut, then dirt must be imported onto the building site. The time required to calculate cut and fill with the grid method is about eight hours for a single sheet site plan of moderate complexity. Lay your plan out on a smooth level service, and with a T-square, divide your plan with a number of equally spaced horizontal lines.

On a piece of graph paper, preferably 11 x 17", plot out the existing elevations from the beginning to the end of each cross-section line. The vertical axis is for elevations and the horizontal axis is for the distance along the cross-section. Then for each cross-section, plot out the proposed elevations from the beginning to the end of each cross-section line on the same graph as the existing. For each cross-section, count the number of squares where the existing line is above the proposed line. For each cross-section, cout the number of squares where the existing line is below the proposed line.

For each adjacent pair of cross-sections, average the cut area between the two and multiply it by the distance between the two cross-sections to calculate your cut volume. For each adjacent pair of cross-sections, average the fill area between the two and multiply by the distance between the two cross-sections to calculate your fill volume 8. Now add up all of your cut volumes and divide them by 27 to get the total cut volume for your site in cubic yards. Add up all of your fill volumes and divide them by 27 to get the total fill volume for your site in cubic yards. To determine the export for your site, subtract the fill volume from the cut volume. If this is a positive number, then you have more cut than fill so you'll need to export material from your site.

If the numbers negative you have more fill than cut, and you will need to import material onto your building site. The second method used to calculate cut and fill is called the cross-section method. In this method, the estimator draws a set at equally spaced horizontal lines across the site plan separated by 1 to 2 inches. Then for each cross-section line the estimator plots out, on graph paper, both the existing surface and the proposed surface vs. the distance along the cross-section.

He then counts the number of grid squares where the existing surface is above the proposed surface. He then counts up the number of grid squares where the existing surface is below the proposed surface. He repeats these steps until all of the cross-sections for the site plan are completed. Then he averages the cut area between each pair of cross-sections and multiplies that by the distance between the cross-sections and divides that number by 27. This is the cut volume between the adjacent cross-sections. He then repeat these steps for the fill areas to determine the fill volume between all the adjacent cross-sections.

He then sums up all of the cut volumes and all of the fill volumes in order to determine the total cut and fill for the building site. If there is more cut than fill, then dirt must be removed from the building site. If there is more fill than cut, the dirt must be imported onto the building site. The time required to calculate cut and fill with the cross-section method is about 20 to 30% longer than the grid method.

The grid method involves drawing a uniform grid onto a plan of the earthworks project, and taking off the existing and proposed ground levels at each node of the grid. With these values the average depth of cut or fill required on each cell of the grid is calculated, and the volume for each cell is obtained by multiplying the depth by the cell area. By adding the volumes for each cell together the total cut and fill volumes for the project can be estimated. The cut or fill depth for each cell is found by subtracting the average existing level of the cell from the average proposed level. If the resultant depth is positive then this is a fill cell, while a negative value indicates a cut cell. In either case, the volume is calculated by multiplying the cut of fill depth by the area of the grid cell.

Nacrtak Earthwork usually represents the largest cost component in the construction of low-volume forest roads. Accurate estimates of earthwork volume are essential to forecast construction costs and improve the financial control of road construction operations. Traditionally, earth-work volumes are estimated using methods that consider ground data obtained from survey stations along road grade lines. However, these methods may not provide accurate estimates when terrain variations between survey stations are ignored.

In this study, we developed a computerized model to accurately estimate earthwork volumes for the proposed forest roads by using a high-resolution digital elevation model . We applied our model to three hypothetical forest road layouts with different ground slopes and terrain ruggedness conditions. We examined the effects of various cross-section spacings on the accuracy of earthwork volume estimation assuming that 1-meter spacing provides the »true« earthwork volume. We also compared our model results with those obtained from the traditional end-area method. The results indicate that as cross-section spacing increases the accuracy of earthwork volume estimation decreases due to lack of the ability to capture terrain varia-tions.

We quantified earthwork differences, which increased with terrain ruggedness rang-ing from 2 to 21%. As expected, short cross-section spacing should be applied to improve accuracy in earthwork volume estimation when roads are planned and located on hilly and rugged terrain. This method involves drawing horizontal and vertical lines over your site plan to divide it into grid cells of equal size.

You then include the existing elevation and proposed elevation for each corner of the grid cells, and work out the difference between the two, as this will be cut or fill depth for that spot. When you've done this for every corner you add them up, average them, and perform further calculations that will end up giving you a total number of cuts and fills. The difference between these two numbers will show you if earth will need to be removed or brought onto site to complete the job. We are frequently asked to provide budget costings for projects with scant information and no Bills of Quantities.

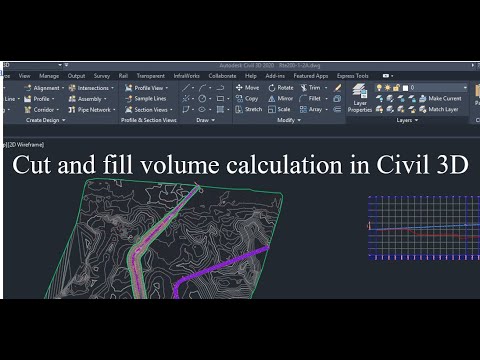

We are also able to produce 3D renderings and cross sections through the site for the client and highlight any problem areas that might exist. DTM Map allows us to determine changes to the consultant's proposed earthworks design to balance cut and fill requirements, thus saving the client money, a service which is greatly appreciated. We have found that we can use the software for applications outside of the intended purchase function; an example of which was the design for the extension of the runway on Mustique. Measurement for valuation purposes is another of the software's strengths, with volume calculations being a particularly powerful tool. The third and final method to calculate cut and fill for building site is to use excavation software. In this method elevation data is either traced off of paper site plan using a large format digitizer, traced on screen using a PDF of the building site plan or imported directly from an AutoCAD file.

How Do You Calculate Cut And Fill By Hand The computer then analyzes the drawing in order to build both the existing and proposed surfaces. The time required to calculate cut and fill using excavation software is about one quarter of the time required for the grid method. Reliable and accurate earthwork calculation is one of the most important components in road engineering that can influence the construction cost and road alignment choice.

In this research, the method of ground penetrating radar was applied to detect the subsoil rock share in forest road construction. The GPR data acquisition was carried out using a 250 MHz GPR antenna along 22 segments on the centerline and 12 meters across to the road project. The GPR data processing was done by performing different filters, such as background removal, migration, band pass filter, and horizontal and vertical smoothing on the GPR data.

To investigate the capability of the GPR method used in this road construction project, we compared the GPR radargram and road profile after construction. The results indicated that the maximum penetration depth of the GPR waves produced by a 250 MHz GPR transmitter antenna, which were between 2 and 5 meters in fine area and rocky grounds, respectively. Moreover, the capability of GPR to map large dimension roots and water content is presented in this work. The grid method of calculation involves drawing a grid onto the plan for the earthwork project. For each node of the grid, determine the existing and proposed ground level and calculate the cut or fill required.

Once the cut or fill depth is calculated, multiply the value by the area of the grid cell. Do this for each square of the grid, then add the volumes together to determine the total cut and fill volumes for the project. The same is done for the fill cells to get the total fill volume. As with the cross-section method, the accuracy of the grid method depends upon the size of grid cell which is used.

A compromise has to be made between the accuracy which is required, and the time which will be taken to produce the estimate. An advantage of the grid method are that the basis of the estimate can be fully summarised on the site drawings, which presents a very clear summary of the calculations for others to check. One of the disadvantages are no graphical summary is generated for the estimation.

Also, like the section method, the grid method is time-consuming and tedious to implement. Different software products use different methods to generate the estimate. Some will essentially apply the grid method described above on a fine-resolution grid, whereas others use a triangulation of the terrain to calculate volumes directly. In any case, the processing power of modern computers means that a high level of accuracy can be achieved in a fraction of the time it would take to produce a manual estimate. There are many advantages to using software to calculate earthworks volumes, and most companies which estimate earthworks on a regular basis will use software to do so. Perhaps the principal advantage of software is that it is much quicker to produce a more accurate estimate when compared with the manual methods described above.

Another major advantage is that most modern software products of this type will have useful display options which can be exported for presentations. Shading cut and fill depths across the project is a particularly useful facility. Rightly or wrongly, people tend to be more impressed by computer-generated images than they are by hand calculations, and trust them more.

This is particularly important when presenting your estimates to a client as part of a tender. The primary disadvantage of using software to produce estimates is the cost of the software licence, which varies between around $200 to several $1000s. The Grid Method involves drawing grids, which are vertical and horizontal lines creating boxes of equal sizes. For each corner of the grid cells, include the existing and proposed elevation then calculate the difference. This will show the required cut when the existing elevation is higher and required fill when the proposed is higher.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.